Description and Specification for Lab Tenders

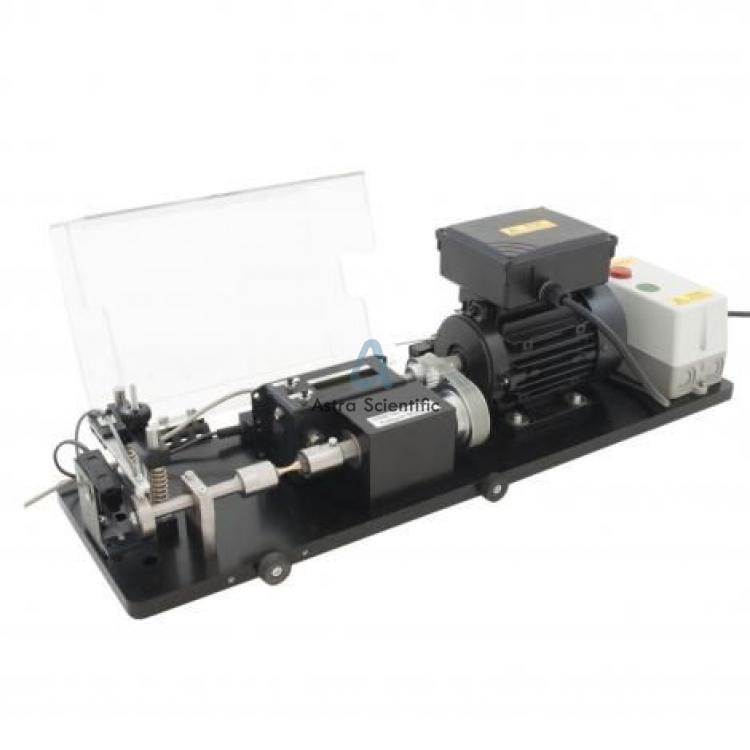

Rotating Fatigue Machine.

The specimens are held within chucks and loaded using a cantilever arrangement, with the load being applied through a screw jack mechanism with integral cantilever load cell.

Both values can be reset and zeroed (tared) prior to the testing commencing. When specimen failure occurs, a micro switch stops the motor and the cycles to failure are registered on the digital display. This unit has been designed to introduce students to the effects of material fatigue using a sinusoidal variation of bending stress.

All tooling is provided to allow the removal and fitting of these specimens. A digital interface displays the applied force and revolution count of the specimen. Specially machined necked test specimens are provided in steel. These have a 4mm nominal neck diameter.

The count remains when the motor is not running. A safety guard shields all rotating parts. A full technical Instruction manual is supplied, which details full unit operation, experimental technique, example results and relevant theory.