Description and Specification for Lab Tenders

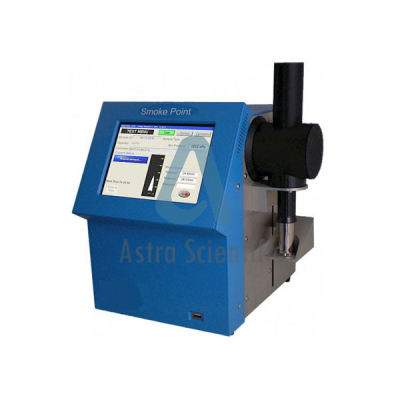

Astra Scientific Automatic Smoke Point Apparatus.

Standard: ASTM D1322, IP 598

The Smoke Point method, in accordance with ASTM D1322, IP 598, is one of

the oldest test methods in the petroleum industry. This test method

provides an indication of the relative smoke producing properties of

kerosenes and aviation turbine fuels in a diffusion flame. The smoke

point is related to the hydrocarbon composition of such fuels.

Generally, the more aromatic the fuel, the smokier the flame. A high

smoke point indicates a fuel of low smoke producing tendency. Performing

the smoke point test manually requires highly skilled technicians with

years of experience. Additionally, the manual test is time consuming.

The current visual rating method used for specification purposes suffers

from the drawback of operator subjectivity. The visual measurement of

an open flame is a challenging exercise and dangerous for lab personnel.

The visual rating of the flame varies from one operator to another.

The Revolutionizes Smoke Point Testing

This unique automated instrument uses a patented system (License TOTAL

RM) based on a video camera that measures the flame. The flame image is

digitalized. The dedicated software determines the height of the flame

when its shape corresponds to the one described in the test method. This

specific flame is the one with the maximum height without smoke

generation. The SP10 performs three determinations of the flame heights

and reports the average value in strict accordance with the test method.

The results are saved in an internal database and can be printed,

transferred to a USB memory stick and/or sent to a LIMS. Every test is

fully documented and traceable, which is imperative for aviation

industry quality procedures.

The SP10 is an Automated Smoke Point instrument that strictly follows

the test method while both eliminating the subjectivity inherent to the

manual test and significantly improving repeatability and

reproducibility. Additionally, the SP10 eliminates all safety risks

linked to the visual observation of an open flame. The test can now be

run unattended which drastically reduces labor costs.

Technical Points Description

Test duration Less than 10 minutes

Resolution (flame height) 0.1 mm

Repeatability and Reproducibility r=0.6 and R=0.9

Four times better than manual test method (r=2.8 and R=3.8)

Parameters saved with a test result Smoke point in 0.1 mm (according

to selected test method), Sample type, Sample ID, Date and Time,

Barometric pressure, Operator name, Test method, Calibration

information, Instrument serial number, Software version

Results storage Up to 100 000 results

LAN connectivity Ethernet port RJ45

Printer output Serial port (printer is optional)

Data output USB(2), Ethernet

Dimensions W x D x H (mm): 330 x 390 x 413

W x D x H (inches): 13" x 15" x 16"

Weight 10kg (22lb)

Electrical 112 to 230V - 2A - 50/60Hz

The smoke point test with the SL-FT-010 is as simple as is a flash point

test with an automated instrument. The operator prepares the candle

according to the test method instructions (phase 1). The candle is then

positioned on a conveyor (phase 2). The operator keys in all sample

details and then initiate the test (phase 3).

Then all the procedure is automated. The candle is automatically lit,

the five minutes stabilization time is followed by the three

determinations of the flame height. At the end of test, the SP 10

instrument calculates the mean value of the three flame heights

measured. The result is rounded then corrected with the memorized lamp

correction factor and finally reported according to the format specified

in the test method. The result is saved in a built-in data base. It can

be printed, transferred on a USB memory stick and/or send to a LIMS

when the SP 10 is connected to a LAN. The lamp factor correction is

automatically calculated and used for result reporting.